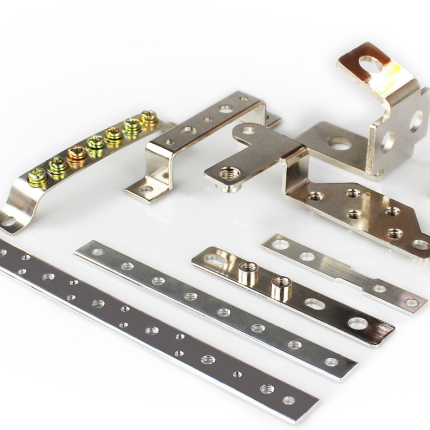

A copper busbar is a solid, flat, or cylindrical strip of high-conductivity copper used for electrical power distribution. It serves as a critical component in electrical panels, substations, switchgear, and industrial power systems due to its low electrical resistance, excellent thermal conductivity, and high mechanical strength.

The copper busbar has become the industry standard for efficient power transmission because of its exceptional electrical and thermal performance, ease of fabrication, and durability.

Composition of Copper Busbar

Copper busbars are made from electrolytic tough pitch (ETP) copper (C11000) or oxygen-free high conductivity (OFHC) copper (C10200), depending on the required electrical and mechanical properties.

Common Copper Grades Used in Busbars

| Copper Grade | Composition | Electrical Conductivity (% IACS) | Oxygen Content | Application |

|---|---|---|---|---|

| C11000 (ETP Copper) | 99.90% Cu | 100% | 200-400 ppm | Standard electrical busbars |

| C10200 (OFHC Copper) | 99.95% Cu | 101% | <10 ppm | High-purity, critical power applications |

| C10100 (OFE Copper) | 99.99% Cu | 101% | 0 ppm | Aerospace, medical, and vacuum applications |

ETP copper (C11000) is the most widely used due to its excellent conductivity and cost-effectiveness, while OFHC copper is preferred for high-frequency and ultra-pure electrical systems.

Properties of Copper Busbar

1. Electrical Conductivity

Copper busbars have superior electrical conductivity, making them ideal for low-resistance, high-current power distribution.

| Property | Value |

|---|---|

| Conductivity | ~5.8×10⁷ S/m (Siemens per meter) |

| Resistivity | ~1.68×10⁻⁸ Ω·m |

| Current Carrying Capacity | High (Varies with cross-section) |

2. Thermal Conductivity

Copper busbars efficiently dissipate heat, reducing thermal stress and preventing overheating.

| Property | Value |

|---|---|

| Thermal Conductivity | ~385 W/m·K |

| Melting Point | ~1,085°C |

3. Mechanical Strength

Copper busbars offer excellent mechanical strength, ensuring they remain durable under mechanical stress, electrical loads, and environmental exposure.

| Property | Value |

|---|---|

| Tensile Strength | 200-400 MPa (depends on temper) |

| Hardness | 40-90 HB (Brinell) |

| Elongation | ~30% |

4. Corrosion Resistance

Copper has natural corrosion resistance, particularly against oxidation and chemical exposure. Nickel-plated or tin-plated busbars offer enhanced protection in harsh environments.

5. Machinability & Formability

Copper busbars can be easily fabricated, bent, and drilled to fit custom designs.

| Property | Value |

|---|---|

| Machinability Rating | ~20% (Compared to free-machining brass = 100%) |

| Weldability | Excellent |

| Formability | High |

Equivalent Standards for Copper Busbar

Copper busbars are manufactured according to international ASTM, DIN, BS, and IEC standards to ensure consistency and performance.

| Standard | Equivalent Grade |

|---|---|

| ASTM B187 | C11000, C10200, C10100 |

| EN 13601 | CW004A, CW008A |

| BS 2874 | C101, C103, C106 |

| DIN 40500 | SF-Cu, OF-Cu |

| JIS H3140 | C1020, C1100 |

These standards define the chemical composition, mechanical properties, electrical conductivity, and manufacturing tolerances for copper busbars.

Why Copper Busbar Became the Standard in Electrical Systems?

Copper busbars have become the preferred choice in electrical systems due to their unmatched performance in conductivity, durability, and thermal management. The transition from aluminum to copper in many industries was driven by the need for lower electrical losses, reduced maintenance, and longer operational life.

- Higher Efficiency → Lower energy loss and improved power distribution

- Compact Design → Higher current capacity in a smaller cross-section

- Longer Lifespan → Corrosion resistance ensures decades of service

- Reliability in Extreme Conditions → Withstands temperature fluctuations and mechanical stress

With advancements in smart grids, electric vehicles (EVs), and renewable energy systems, copper busbars continue to play a crucial role in modern electrical infrastructure.